‘PackML’ stands for Packaging Machine Language, a guideline drawn up by the Organization for Machine Automation and Control (OMAC). This organisation is supported by large, globally operating manufacturers of consumer products such as Nestlé, Procter & Gamble and PepsiCo. In collaboration with system integrators, machine builders and technology suppliers, they want to create open standards for the vertical and horizontal integration of machines. ‘Horizontal integration’ refers to the interaction between the machines themselves (machine-to-machine communication), and ‘vertical integration’ to linking this with central control systems.

Qimarox’s alignment with PackML means that its palletisers, vertical conveyors and other machines are now even easier to integrate, operate and maintain. Manufacturers of consumer products using PackML as a guideline succeed in bringing new production and/or packaging lines into use three to four months earlier. They are seeing the total cost of ownership (TCO) of their systems fall significantly, while the overall equipment effectiveness (OEE) increases. System integrators and machine builders who incorporate Qimarox modules into their solutions also benefit from the simplified integration and acceleration of test procedures.

Conditions for innovation

Standardisation in the realisation of production and packaging lines is desperately needed. Standards allow manufacturers to shift gears quickly and adapt their production processes to the rapid changes in the market. OMAC is currently preparing to enable concepts such as plug-and-play and plug-and-produce in due course. ‘PackML increases the possibilities for innovation. If manufacturers want to update a system, they don’t need to modify the control system of an entire packaging line. They only need to concentrate on the parts that need to be updated,’ says Uwe Keiter, chairman of the OMAC Packaging Workgroup.

In order to take full advantage of new technologies such as the Internet of Things (IoT) or artificial intelligence (AI), standards are also indispensable. ‘Today, we can store and analyse data from different machines in the cloud. However, this is only really useful if we record the data identically, so that we can for example compare the performance of machines and calculate the OEE unequivocally. PackML makes that possible,’ says Keiter, who in his everyday life works as Business Development Director / Consumer Goods for technology provider Lenze.

Agreements in three areas

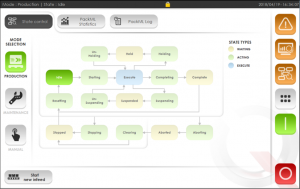

PackML comprises agreements in three areas. The first area concerns the status of the machine. If the status is ‘idle’, then it is ready to produce. With a start button, the operator can then actually start the machine, after which the status will change to ‘execute’. If there is a fault, the status will switch to ‘held’. Thanks to the uniform set of agreements, operators can operate a new machine without any training and service engineers can quickly find out which part of the production or packaging line has the problem.

The second area concerns the mode of operation of the machine. Is it set to ‘automatic’, ‘manual’ or ‘maintenance’? Thirdly and lastly, agreements have been made about the way in which data is exchanged between the machines themselves and with the overlying control system. This could include, for example, the speed of the machine: will it be specified in metres per second or in units per hour? It has also been established that each machine will only exchange data with the machines immediately before and after it in the line. ‘If machine B has a fault and the status jumps to ‘held’, this is only passed on to machine A and C, but not to machine D. Machines A and C can respond to this by reducing their speed, which means that the status will change to ‘suspended’. Machine C in turn passes this status on to machine D’, explains Keiter.

PackML as a prerequisite

PackML offers advantages not only for end users and system integrators, but also for Qimarox and other machine builders. The OMAC guidelines make it easier to also design the control system of machines in a modular way. When upgrading, they only need to modify the module, not the complete machine. This reduces the time needed for testing and troubleshooting. In a factory acceptance test, there is no longer any need to test the communication with other machines, which can result in time savings of 60%. There is also no need to keep reinventing the wheel when programming the machine: 80% of the software can be reused.

Integration with packml guidelines

By adhering to PackML, Qimarox is responding to market demand. ‘More and more manufacturers of consumer products are including PackML as a precondition in their request for a quotation. By meeting PackML’s specifications as standard, we make it easier for our own customers – system integrators and machine builders – to meet these requirements,’ says Jaco Hooijer, Operations Manager at Qimarox. ‘In addition, we recognise the importance of standardisation in the industry. By becoming a member of OMAC we want to contribute to the further spread and adoption of PackML’.

Everyone benefits

OMAC is happy with the registration of Qimarox. More and more machine builders are adopting PackML, according to Keiter. ‘We can buy machines anywhere and link them together to form a production or packaging line. However, most machines’ software is not consistent, simply because it was created by different programmers. This makes it difficult to connect these machines to, for example, a MES (Manufacturing Execution System). It also means that operators and service engineers have to be re-trained for each machine. Everyone in the industry benefits from guidelines like PackML, both users and suppliers of production resources’.