Casestudy Qimarox Eslogic – DeltaStar increases order-picking capacity with vertical conveyor

DeltaStar Nutrients has successfully expanded its order picking capacity with a new mezzanine floor. The undisputed eye-catcher in the Venlo warehouse is the Prorunner mk5 from Qimarox, which transports plastic containers from the mezzanine to the ground floor. System integrator Eslogic installed and integrated this vertical conveyor in just three days. Peter Gatzen of DeltaStar is happy with the purchase. “This is a reliable, simple and clear system that fits perfectly into our business operations.”

In 1994, DeltaStar Nutrients was one of the first pioneers in nutritional supplements. The company began importing high-quality nutritional supplements from American brands such as Natures Plus and Allergy Research Group. “We now offer an assortment of almost a thousand products, including our own product line Vitaplex. We supply doctors, therapists and their patients in all German-speaking countries and the Benelux,” says Peter Gatzen, CEO of DeltaStar.

In 2019, the wholesaler moved to new premises on the Brightlands Campus in Venlo. The old warehouse had become too small and no longer met today’s requirements. “Our new accommodation is located in an environment with knowledge institutions, research laboratories and companies that specializes in the field of nutrition and health. That invites collaboration. In addition, we now have a representative building in which we are happy to receive doctors and therapists”, explains Gatzen.

More capacity with an extra floor

In the new warehouse, order pickers walk along the products with carts to collect them in plastic containers. DeltaStar has asked the help of Eslogic for the transport of the containers to the packing department. In the summer of 2019, this system integrator installed a simple but effective system with a roller conveyor and six packing tables.

Less than a year after commissioning, DeltaStar was once again looking to expand its order picking capacity. The reason was the rapid growth and increase in the number of Stock Keeping Units (SKUs). “We decided to create an extra floor by building a mezzanine,” explains Gatzen. “This includes a new challenge: vertically transporting the plastic containers from the mezzanine to the ground floor. We have again asked Eslogic for help.”

Much less space occupied

Eslogic has mapped out various options, including roller conveyors and belt conveyors. These have the disadvantage that the difference in height can only be bridged with a small angle of inclination. This means that a roller conveyor or a belt conveyor takes up a lot of space. That is why a vertical product lift was preferred. The investment costs are higher, but the space required is much less,” explains Paul Zeebregts, owner of Eslogic.

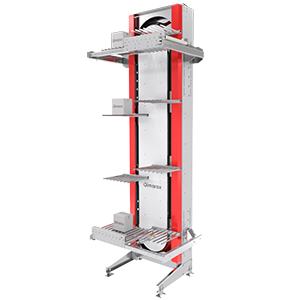

The choice was made to use a Prorunner mk5 from Qimarox. This vertical conveyor consists of several forks (product carriers) that circulate according to the paternoster principle. The forks pick up the plastic containers from a roller conveyor on the mezzanine floor and deposit them on a roller conveyor on the ground floor. The container can then go in two directions: towards the racks for the missing products or directly to the packing tables.

Real eye-catcher

Before the choice was made, Eslogic and DeltaStar visited the Qimarox Headquarters in Harderwijk together to have a demo presentation. They were quickly convinced once they saw the Prorunner mk5. “We could also have used a conventional product lift, but this is an elegant and simple system with comparable investment costs,” says Zeebregts, who is supported by Gatzen. “The Prorunner mk5 is a real eye-catcher in our warehouse. That is important, because we want to emanate quality, also in logistics.”

The Prorunner mk5 from DeltaStar is 5.20 meters high. The first design had two product carriers, but has been expanded to five for expected growth in the future. By expanding it from two to five, the vertical conveyor can handle as many as 1200 plastic containers per hour, much more than the capacity that the Venlo wholesaler needs at the moment. “The capacity is not the most important aspect for us,” says Gatzen. “The most important thing is that we have a reliable, effective and simple system that fits perfectly within our operation and our philosophy.”

In accordance with planning and budget

For Eslogic, the installation of the Prorunner mk5 marked the first collaboration with Qimarox. The collaboration went very well and went according to plan and budget without any setbacks. “The Prorunner mk5 was delivered on time and was ready for use within three days. This machine has only one electric motor and built-in, wired sensors with one connection point. Making the connection to the control cabinet was quick and easy,” explains Zeebregts.

Energy consumption

The by Eslogic developed control software ensures that the Qimarox Prorunner mk5 and the roller conveyors for the infeed and outfeed of containers work together perfectly. “We have designed the controls in such a way that the conveyor automatically stops if there is no product infeed for a while. As a result, no unnecessary energy is wasted,” says Zeebregts. That particularly appeals to Gatzen. “We are here in an energy-neutral building without a gas connection and with solar panels. Sustainable use of raw materials and energy is high on our priority list.” Another advantage of the product lift is that the lift works according to the paternoster principle, which means that the (empty) lift itself is always in balance, so energy is only used for lifting the product. As a result, a relatively small drive can suffice for lifting several product carriers.

Competitive price

The Prorunner mk5 works excellent. The reliability of the machine is very high, malfunctions are almost non-existent. An additional advantage: the vertical conveyor makes little noise, which is great for the order pickers on the work floor. “It is a standard solution with proven technology and a competitive price from a supplier with a lot of experience,” emphasizes Zeebregts. Gatzen: “I am proud to have this vertical conveyor in our warehouse. This is a solution with which many other companies can also significantly improve their efficiency.”