Tell us what you want to make. We make it possible.

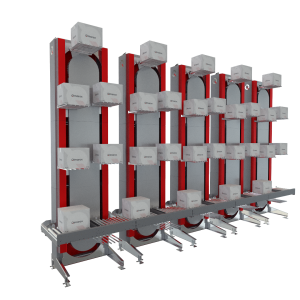

Each product is different. Each product environment is different. That is why at Fraxinus we believe that each machine must be different. That is why we specialised in the design and production of tailor-made machines and handling systems

Your Production can be more efficient too

Fraxinus examines how you produce today and make the difference tomorrow. We check how your employees can work even more efficiently in an even more pleasant environment. We analyse and fine-tune the machines you work with:

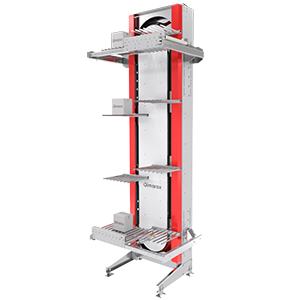

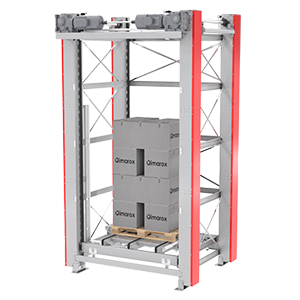

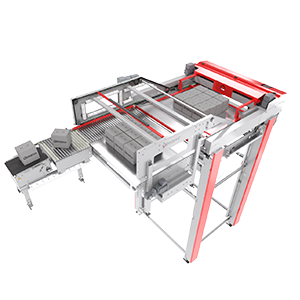

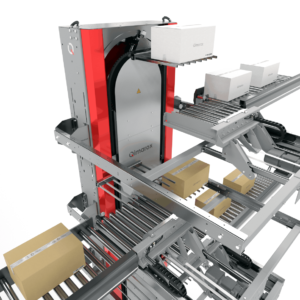

- robot projects

- manipulators

- conveyor systems

- packaging lines

- packaging lines

Fraxinus, What’s in a name?

The name Fraxinus, the Latin word for ‘ash tree’ refers to the name of the man who has founded the company in 2004. Hans Van Essche (Dutch for ‘ash tree’) is still the driving force behind Fraxinus today.

The ash tree (Fraxinus excelsior) also symbolises what the company stands for: sustainable growth. Ash wood is tough and strong. And yet flexible. It was traditionally used for tools, such as axe and spade handles. This tradition has been kept alive by Fraxinus. By making your work more efficient and pleasant by means of clever machines and automation projects.

Fraxinus NV

Wijnendalestraat 162

8800 Roeselare

Belgium

T: +32 51 30 78 53

E: info@fraxinus.be