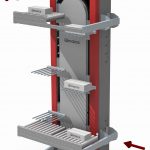

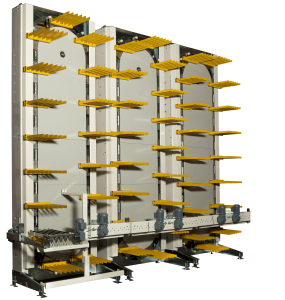

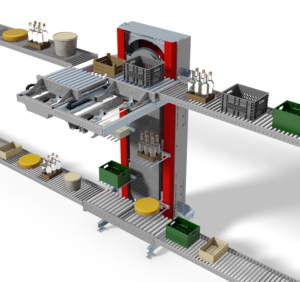

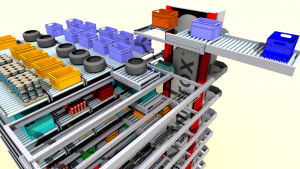

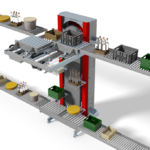

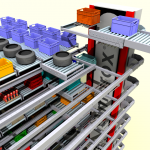

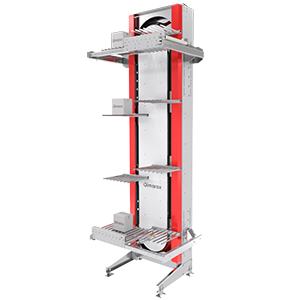

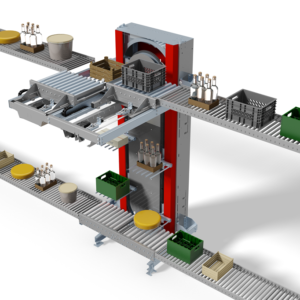

The Prorunner mk5-XL continuous vertical conveyor is suitable for average to high capacity applications. It is perfect to transport (bigger) products vertically up and down.

Continuous vertical conveyor - Prorunner mk5-XL

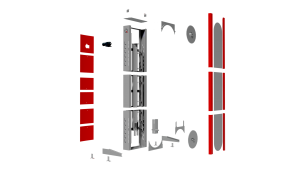

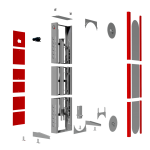

The Prorunner mk5-XL is designed for when you want to handle bigger products than the regular Prorunner mk5 can handle. This continuous product lift is still module-based and it offers a maximum capacity of 2,000 products per hour. The modular buildup of our vertical conveyors in general offers another benefit, which is that the shipment volumes are smaller and therefore shipment costs are cheaper. Our continuous vertical conveyor Prorunner mk5-XL is used to effortlessly and quickly transport a wide variety of (bigger) products vertically.

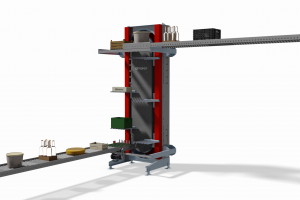

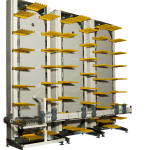

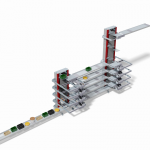

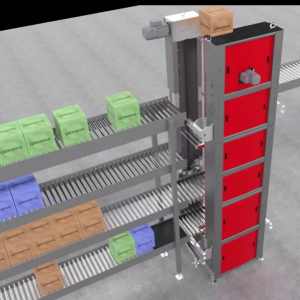

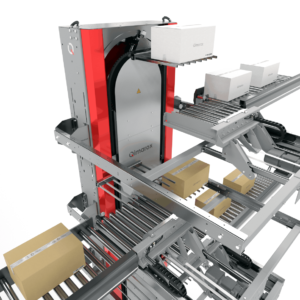

The Prorunner mk5-XL is also an energy-efficient product lift, which can be used to quickly transport products up or down. It is also possible to have products to be transported up while also bringing another batch of products down. Products like boxes, cases, trays or bags can be transported to and from a height up to 17.3 meters / 56 ft 10 inch. The products are always carried in an upright position so there is no risk of product deformation.

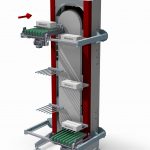

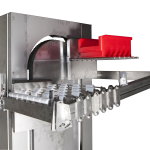

The Prorunner mk5-XL is capable to lift bigger products! Like already mentioned above, our continuous vertical conveyor can be used for both ascending and descending product flows at the same time! This versatile vertical conveyor is even suitable to function as a vertical sorter by adding retractable conveyors at the in and outfeed. Find out more here.

Why choose Qimarox?

Qimarox is a leading manufacturer of components for material handling systems. As a manufacturer of palletisers and product lifts, Qimarox distinguishes itself with a contemporary vision and approach. Innovation, quality and added value are of paramount importance. For more information about our Prorunner mk5 watch our YouTube video.

Interested in the continuous vertical conveyor - Prorunner mk5-XL or a different vertical conveyor solution?

If you would like more information about our vertical conveyor solutions, you can request a sales enquiry without any obligations. If you have any other questions please feel free to contact us!

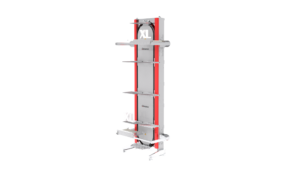

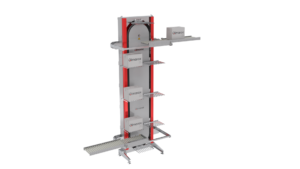

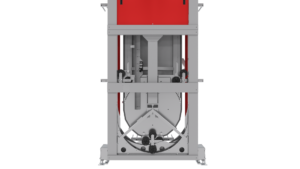

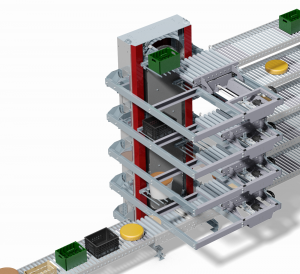

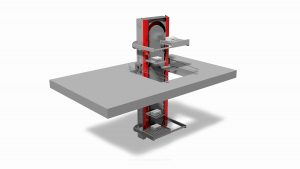

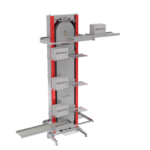

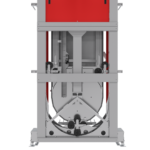

The Prorunner mk5-XL is a fully module based continuous vertical conveyor that can be easily assembled in almost any configuration. The continuous vertical conveyor system incorporates highly reliable components that offer an extremely long service life. Maintenance is restricted to an absolute minimum.

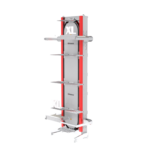

The specifications for the Prorunner mk5-XL are:

• Lowest infeed/outfeed position of the mk5: 810 mm / 32 inch

• Highest infeed/outfeed position of the mk5: 17,300 mm / 680 inch

• Max column height: min. aprox. 18 mtr / 705 inch

• Drive System: SEW 0,55 - 4,0 kW

• Max. product weight: 50 kg per carrier / 110 lbs per carrier

• Max. product size: - 900 mm x 610 mm x H / 35 inch x 24 inch x H

• Throughput: 1 carrier for 200 products per hour (add further carriers for higher capacities)

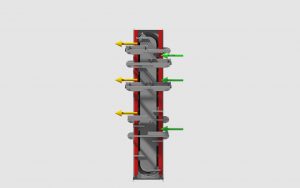

• Configuration: B3 or C2 for elevating, 6G or 7F for descending (more options become available with a different type of carrier)

• Securyfence Safety Fencing H=2120 mm (83.47")

• Pitch Product Carrier 75 mm (2" 61/64)

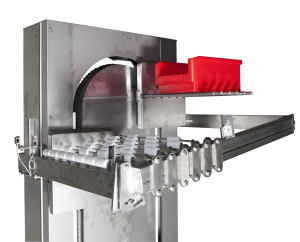

• Infeed Conveyor: gravity roller conveyor / powered roller conveyor / belt conveyor / shuttle roller conveyor

• Outfeed Conveyor: gravity roller conveyor / powered roller conveyor / belt conveyor / shuttle roller conveyor

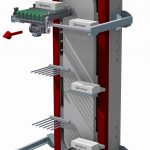

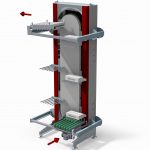

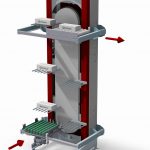

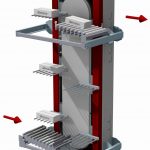

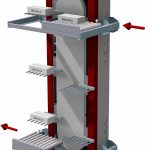

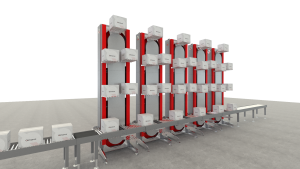

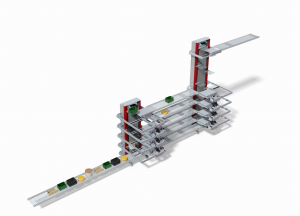

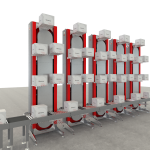

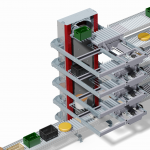

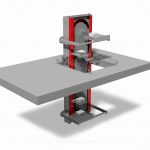

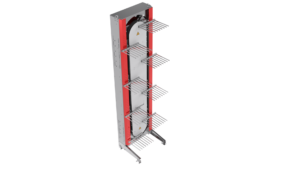

Prorunner mk5-XL Configurations

For example, if you would like to elevate your products, feeding them in at the front and out to the side, choose combination B4 or C1. If you would like to descend your products, feeding them both in and out to the sides, choose combination 8E or 5H.

Elevate

Descend