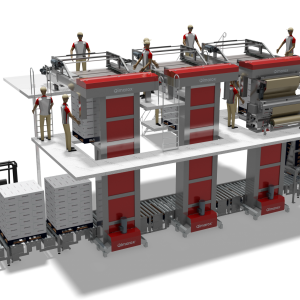

The Highrunner HR9 is designed for the logistics industry and has handling capacities of 500 – 1,500 products per hour.

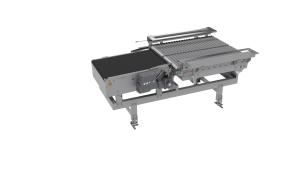

Highrunner HR9: automatically layer pattern selection

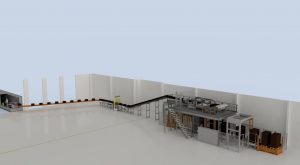

The Qimarox Highrunner HR9 Logistics palletizer is specially designed for logistic operations. Therefore, this machine is very effective where many different products are handled in short batches. Our unique and patented layer-formation system can generate a large variety of layer patterns. These patterns can be selected automatically or generated by the state-of-the-art pattern generator. A specially designed pattern generator will present to you the most optimal layer pattern according to box size and pallet size. As example, if the installation is equipped with a full 3D product scanner it is even possible to have the system working fully autonomously.

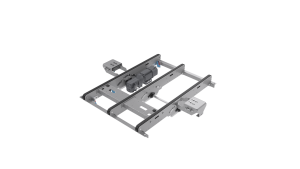

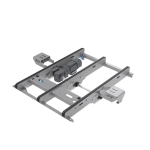

Because the pattern formation system is at high level and the pallet is moving up and down with the pallet lift, (Qimarox Prorunner mk10) higher throughputs can be achieved. The top of the pallet is consequently always located at the same level as the pattern-formation conveyor. As a result higher layer capacity is possible as stacking plates can receive a new layer quickly after a layer is placed onto a pallet.

Layer by layer

The Highrunner HR9 Logistics palletizer is based on the Highrunner HR7. This machine is the fastest, most flexible palletizer from the Qimarox range. What is interesting is that the products are deposited on the pallet layer by layer with this machine. To do so the machine has a built-in buffer, where each formed row remains until a layer is complete. By depositing an entire layer at a time, the Highrunner HR9 needs to make fewer movements. This saves time, which increases the capacity.

Because it is the pallet that is moving up and down with the Highrunner HR9 palletizer, the layers no longer need to be moved up and down while being deposited. As a result time is saved, especially with pallets that need to be stacked 1.80 meters or higher. This makes the Highrunner HR9 one of the fastest palletizers on the market.

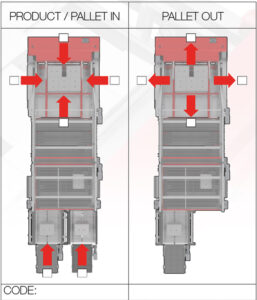

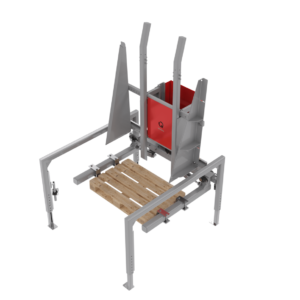

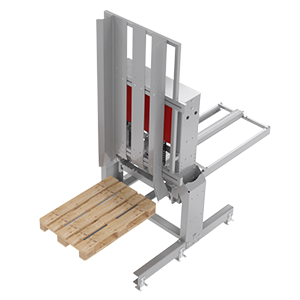

Infeed and outfeed of pallets

As soon as a pallet is full, the pallet lift moves all the way down so that it can be carried away via a pallet transport system. An empty pallet can be supplied from the opposite direction at the same time.

Why choose Qimarox?

Qimarox is a leading manufacturer of components for material handling systems. As a manufacturer of palletisers and product lifts, Qimarox distinguishes itself with a contemporary vision and approach. Innovation, quality and added value are of paramount importance.

Interested in a palletizing machine or another palletizing solution?

If you would like more information about our palletizing solutions, you can request a sales enquiry without any obligations. If you have any other questions please feel free to contact us!

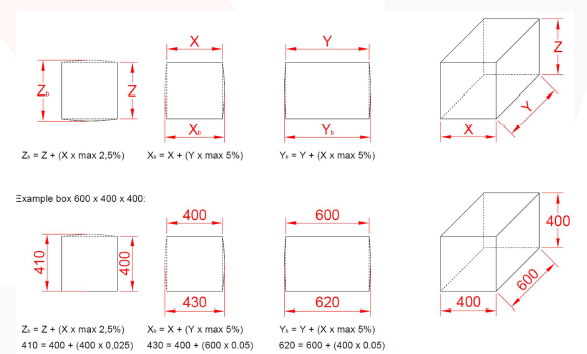

The Highrunner HR9 can hanlde a large variaty of box sizes and layer patterns. Full specifications can be found below.

| Specifications | Min. | Max. |

| Infeed height at platform level (mm/inch) | 600 / 24 | 1,000 / 39 |

| Pallet height (mm/inch) | 600 / 24 | 2,500 / 98 |

| Product (LxBxH mm/inch) | 200 x 200 x 150 / 8 x 8 x 4 | 600 x 400 x 600 / 24 x 16 x 24 |

| Layer (LxBxH mm/inch) | 750 x 500 x 100 / 30 x 20 x 4 | 1,240 x 1,000 x 600 /50 x 40 x 24 |

| Width to height / length ratio | 0.5 / o.5 | 0.5 / 0.5 |

| Throughput(products/hour) | 500 | 1500 |

| Throughput(layers/hour) | 1 | 300* |

| Product weight (kg/lbs) | 1 / 1 | 25 / 55 |

| Layer weight (kg/lbs) | 1 / 1 | 180 / 400 |

*Capacity depends on product dimensions and stacking pattern

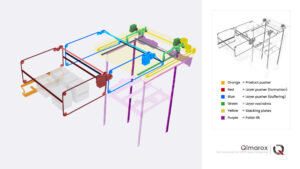

The Highrunner HR9 is build in the most optimal configuration for logistic operations.

- TwistRunner with product measurement (patented product rotation)

- Side infeed: infeed from the right or left next to the formation location

- Layer buffer with layer centering

- Bi-directional apron plate for straight outlined pallets

- Palletlift with pallet centering and alignment to ensure stable loaded pallet

Benefits of the Highrunner HR9

- Unique method of pattern formation, where products are positioned on exact coordinates (patented)

- Prorunner PR10 pallet lift

- Built-in buffer for depositing products in layers

- User-friendly touchscreen operation (Pack ML)

- Freely programmable stacking patterns

- Solid construction with perfect finishing for tough jobs

- Easy access for service and maintenance

- Standard machine with commercially available components