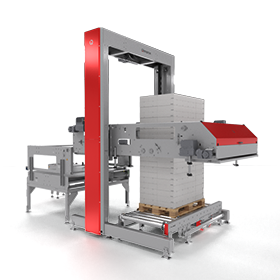

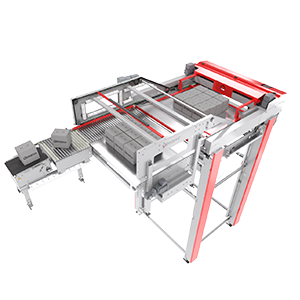

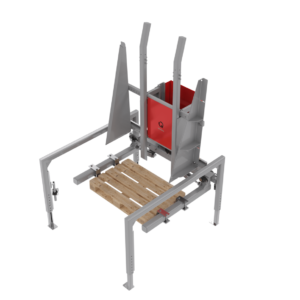

The modular LOWRUNNER LR3 palletizer from Qimarox is a palletizer with a capacity of up to 1,500 packages per hour. It is suitable for an environment where rapid return on investment is desired or necessary. Optionally, the LOWRUNNER LR3 can also be equipped with the Qimarox Sheetrunner to put intermediate sheets between layers.

The modular palletizer Lowrunner LR3 from Qimarox is a palletizer with a capacity of up to 1,500 packages per hour. It is suitable for an environment where rapid return on investment is desired or necessary. Optionally, the Lowrunner LR3 can also be equipped with the Qimarox Sheetrunner to put intermediate sheets between layers. *NOTE: Delivery time to be discussed*

Low level infeed

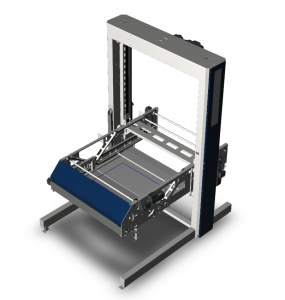

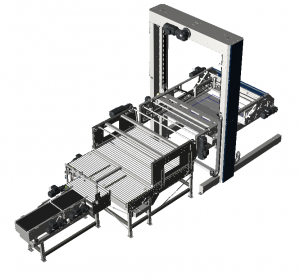

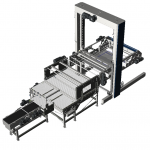

With the Lowrunner LR3 there is no need for an operator platform as the complete layer formation station is placed at floor level. The unique Qimarox layer formation station can place every product on an exact location. This is done with a product pusher that places every product into a row of product. If a layer is completed this layer is placed onto the bi-directional stacking plate. This is an unique feature as most low level palletizers handle layers with a single direction stacking plate. By using a bi-directional stacking plate to put layers onto the pallet the outline of the pallet will be very consistent to get the maximum strength out of a carton box and a solid pallet load is guaranteed. Due to this solution the Lowrunner LR3 palletizer is very suitable for a large variety of products.

The Lowrunner LR3 can handle a wide range of products:

- boxes

- boxes with lids

- trays

- trays with foil

- crates

- etc.

The Lowrunner is modular constructed. This means that several options are available for each module depending on the customer requirements and the products requiring palletization.

In short, you will end up with the system that best suits your needs. However, this system can be completely adapted to changing circumstances in the future thanks to the interchangeability of its modules.

Why choose Qimarox?

Qimarox is a leading manufacturer of components for material handling systems. As a manufacturer of palletisers and product lifts, Qimarox distinguishes itself with a contemporary vision and approach. Innovation, quality and added value are of paramount importance.

Interested in the Lowrunner LR3 or another palletizing solution?

If you would like more information about our palletising solutions, you can request a sales enquiry without any obligations. If you have any other questions please feel free to contact us!

The specifications for the Lowrunner LR3 palletizer are:

| Specifications | Min | Max |

| Infeed height (mm/inch) | 600 / 23 inch | 3.000 / 118 |

| Product dimensions (LxBxH mm/inch) | 150 x 150 x 100 / 6 x 6 x 4 | 600 x 400 x 400 /24 x 16 x 16 |

| Thoughput (products/hour) | 100 | 1500 |

| Thoughput (layers product/hour) | 30 | 120 |

| Product weight (kg/lbs) | 1 / 1 | 25 / 55 |

| Layer weight (kg/lbs) | 1 / 1 | 180 / 400 |

| Footprint (m²/sq ft) | 12 / 130 | 12 / 130 |

Benefits of the Lowrunner LR3

- Unique method of pattern formation, where products are positioned on exact coordinates (patented)

- Pallet building with a bi-directional stacking plate

- User-friendly touchscreen operation

- Freely programmable stacking patterns

- Solid construction with perfect finishing for tough jobs

- Easy access for service and maintenance

- Standard machine with commercially available components

In addition, the palletizer can be expanded with a number of additional modules:

- Twistrunner: for turning products

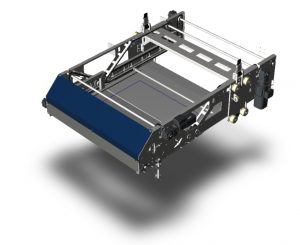

- Sheetrunner: for laying a sheet of cardboard or paper between two layers

- Pallet dispenser: to feed an empty pallet