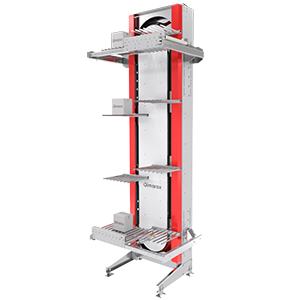

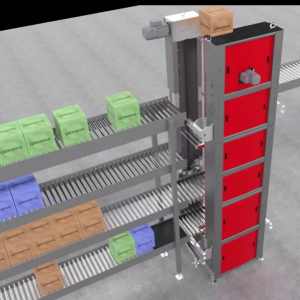

The Prorunner mk1 is a compact and robust discontinuous product lift that requires minimal maintenance and is attractively priced.

Vertical conveyor Prorunner mk1 - Small footprint

The Prorunner mk1 is a discontinuous vertical conveyor with a small footprint that excels in robustness and requires minimal maintenance. Its steel structure is extremely stable under all circumstances.

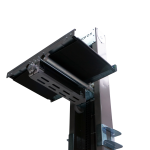

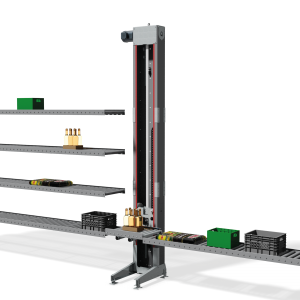

By using a flat belt the Prorunner mk1 is completely silent in its movement. Moreover, a flat belt of this type almost has no maintenance. No lubrication and tension in comparison to chain driven system is needed anymore. Due to the small footprint the machine can be used in almost any factory lay-out.

Efficient vertical transport (Vertical conveyor)

The lift can easily hoist boxes, trays, boxes, crates, boxes or bags weighing up to 100 kg. The Prorunner mk1 is ideally suited for applications where maximum capacity of approximately 420 movements per hour is needed. Its compact design makes it a vertical conveyor with small footprint.

All this together makes the Prorunner mk1 an extremely efficient and economical solution for your vertical transportation.

Why choose Qimarox?

Qimarox is a leading manufacturer of components for material handling systems. As a manufacturer of palletisers and product lifts, Qimarox distinguishes itself with a contemporary vision and approach. Innovation, quality and added value are of paramount importance. For more information on our Prorunner mk1 watch our YouTube video.

Interested in the Vertical conveyor - Prorunner mk1 or another vertical transport solution?

If you would like more information about our vertical conveyor solutions, you can request a sales enquiry without any obligations. If you have any other questions please feel free to contact us!

Prorunner mk1: extremely flexible product elevator

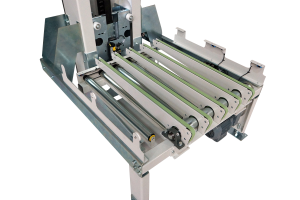

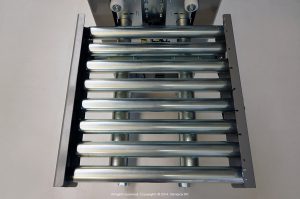

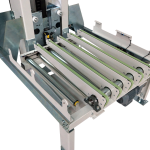

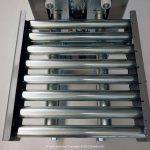

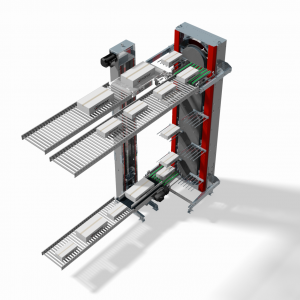

Due to its modular design, the Prorunner mk1 adapts easily to its operating environment. A standard roller conveyor (possibly driven) is included standard as a product carrier. This can optionally be replaced by a belt conveyor or other specific carrier. It is possible to install a custom conveyor without having to modify the construction. In this way, the elevator will optimally connect to the conveyor system in your production or distribution environment.

Customised infeed and outfeed heights

The infeed and outfeed heights may be freely chosen and are in principle not bound to a maximum height. It is also possible to use the Prorunner mk1 to supply multiple infeed or outfeed conveyors, so that the elevator can act as a vertical sorter.

The components that the system is made of are extremely low maintenance and durable.

The vertical conveyor Prorunner mk1 has the following specifications:

- Lowest infeed/outfeed position of the mk1: 360 mm / 14 inch

- Highest infeed/outfeed position of the mk1: 14,300 mm / 555 inch

- Max. Column height: 14,450 mm / 47 feet

- Drive: SEW 0,55 kW

- Max. Product weight: 100 kg / 220 lbs

- Max. Product size: 910 x 610 mm / 36 x 24 inch

- Max. Throughput: 420 p/hour

- Required surface: 500 x 900 mm / 20 x 35 inch

The Prorunner mk1 can be upgraded with various types of product conveyors, such as a belt conveyor or driven roller conveyor. Furthermore, the required machine guard can also be supplied.

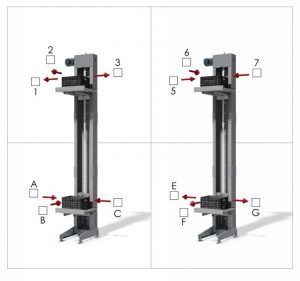

Prorunner mk1: Accept and output products in three different directions

The Prorunner mk1 can be effortlessly integrated into almost any existing setting. The product elevator cannot only accept and output products via the left and/or right sides, but - if an appropriate product carrier is fitted - also from the front.

When configuring your system to best fit your situation, simply follow the step-by-step plan designed to make it easier for you to navigate the various options. You can use the adjoining illustration to help you select your infeed and outfeed options.

Example:

If you would like to elevate your products and feed them in from the left side, but output them to the front, choose combination A2. If you would like the product to descend and to feed the product both in and out to the right, choose combination 7G.