We identify with the three “i”s of integration, innovation and internationalisation. Simultaneously, we rely on four pillars: support of property, knowledge, experience and, fundamentally, much enthusiasm and determination.

ORIGINS

SINTERPACK’s plant was originally founded in Burgos (Spain) in 1965 by the Dutch multinational STORK, a world leader in the dairy sector, to service the industrialisation process of the dairy sector that was taking place in Spain in those years. Though SINTERPACK has been present for many years in other sectors, we keep having a strong presence in the Spanish dairy sector, currently having a market share of around 70% in end-of-line systems. We have implemented solutions in other food sub-sectors (cookies, butter, flour, sugar, canned food, frozen food,…), automotive, paper and celluloses and chemical. That is to say, we have the technology and the experience and, therefore, the capacity to adapt and provide our customers with the best possible solution at an always competitive cost.

WHAT WE DO

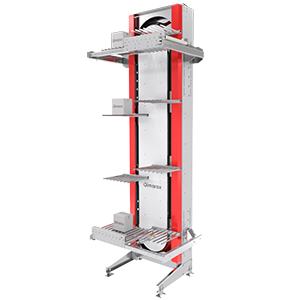

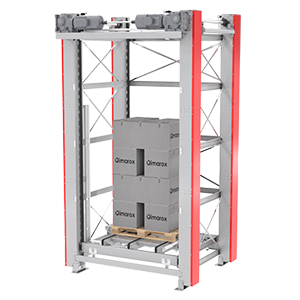

Our portfolio is made up of all those elements and auxiliary equipment that can be integrated in an end-of-line system, starting from a product in its primary packaging until the delivery of a finished pallet in a warehouse or loading dock.

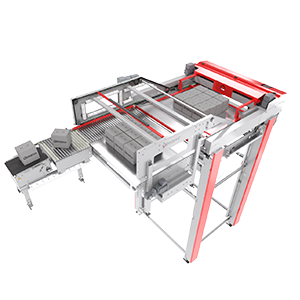

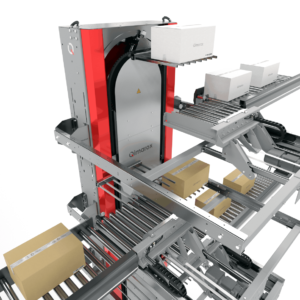

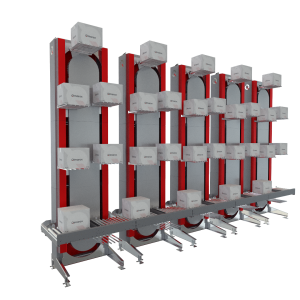

We produce and integrate a wide variety of EOL equipment including those for batching, box-forming, box filling, labelling, transport, stacking, palletising, strapping or wrapping in a wide variety of formats and sectors, always observing the special considerations of the handling of each product. We have the ability to integrate in our systems robots of top brands like KUKA, ABB, FANUC, YASKAWA, etc. controlled by our own programmers, until final delivery of a complete turnkey system.

We integrate cells with tailor-made robot systems, with adapted software for an unlimited number of mosaics thanks to a great variety of clamps (or grippers), which are in turn adapted to our clients’ requirements, because we all know that every product and need are different. All components used are standard.

The modular cell concept used is valid both for small installations with a single palletising station and for centralized palletising systems with up to 30 palletising stations or more depending on customer references…

In these multi-reference cases, these robotic systems integrated by SINTERPACK have significant advantages compared to other conventional palletising options.

We put all our knowledge and efforts into cooperating with our clients to help them stand out and gain competitiveness.

SINTERPACK understands the importance of an efficient production line and our systems are designed and furnished with the characteristics that permit them to work at high speeds without damaging the product.

Our active listening ability together with our designs, precision engineering, reliability and robustness of each of our systems guarantee the achievement of that joint objective of increasing productivity and reducing costs.

The efficiencies or performances -relation between real work time and available time- of our lines are around 99%.

All our systems are assembled and tested in our plant in Burgos, so our clients can see them work before their assembly and final delivery at their own premises, thus significantly reducing the assembly and adjustment times as well as unnecessary interferences in your plants.

Also, we train our customers’ personnel during assembly and start up so that once the installation is started, they can manage the system -and its maintenance- and production simply flows from the beginning reducing operating costs. In any case, we offer tele-assistance and after-sales services.

Sinter Ibérica Packaging S.A.

C/La Ribera s/n Pol. Ind. Gamonal Villayuda

09007 Burgos

Spain

T: +34 947 474 220

E: info@sinterpack.com