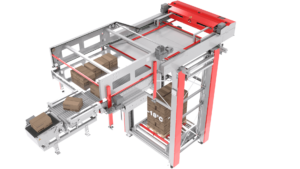

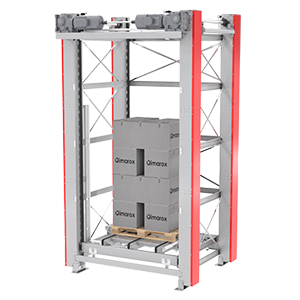

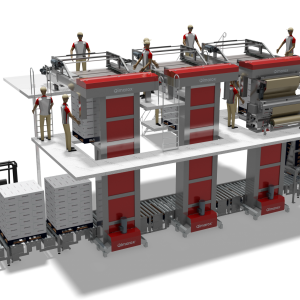

The Highrunner HR8 Palletizer – for IQF products is used for palletizing cartons containing frozen food – mainly vegetables, fries & fruits.

Palletizer Highrunner HR8 for IQF products suchs as Vegetables, Fruits and Fries

Frozen foods industry

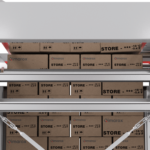

In the frozen food industry, it's important to efficiently manage the storage and transportation of food. That's where palletizers come in. The Highrunner HR8 palletizer is a machine that's designed to efficiently load empty pallets with frozen food products.

There are several reasons why using a palletizer in the frozen food industry is beneficial. First, it speeds up the process of handling the products and the loading and unloading process for transport trucks. Resulting in shorter transportation times and fresher food. Also, using a palletizer helps to reduce labor costs by automating a tedious and physical task. Finally, a palletizer can be programmed to load pallets in a way that optimizes storage space, saving money on storage fees.

In summary, using a palletizer in the frozen food industry has many advantages, including shorter transportation times, reduced labor costs, and optimized storage space.

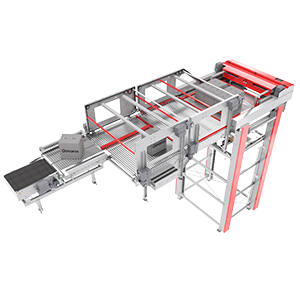

Unique layer formation system

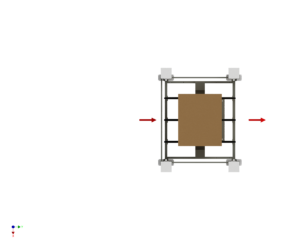

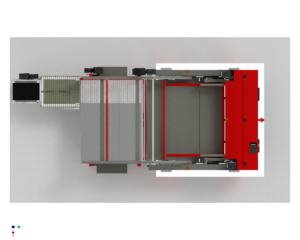

What sets every Qimarox layer palletizer apart from any other solution on the market is the unique way a layer is build. With the patented design every layer pattern used within the frozen food industry can be created without any manual adjustment.

As floorspace is very expensive, the line infeed of the flexible palletizer also ensures the possibility to place machines close next to each other so the machine can be placed in line with the casepacker.

Palletizing cartons with frozen vegetables needs a layer formation system that can handle both normal cartons but also cartons that are bulged due to the - often - lower carton quality and the properties of the natural product that is being packed. By moving and positioning each row of cartons individually it is possible to create exact gaps between the individual row. These gaps are used to absorb the tolerances on the cartons when the layer is placed onto the pallet.

This way of layer handling had proven over-and-over again that it offers the best solution to create solid and stable pallet loads, even with bulged cartons.

Pattern Generator

Every HR8 comes with the commonly used layer-patterns within the industry pre-programmed. Every layer pattern is freely adjustable with the HMI and also complete new layer patterns can be created very easily. This can be done with the Qimarox Pattern Generator and can be used without detailed knowledge on the palletizer. You can simply enter the product and pallet dimensions and the system will show you the most optimal layer patterns to choose from.

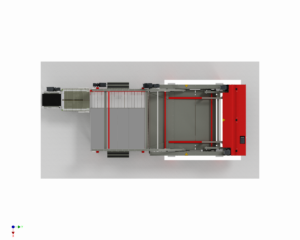

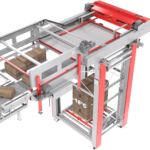

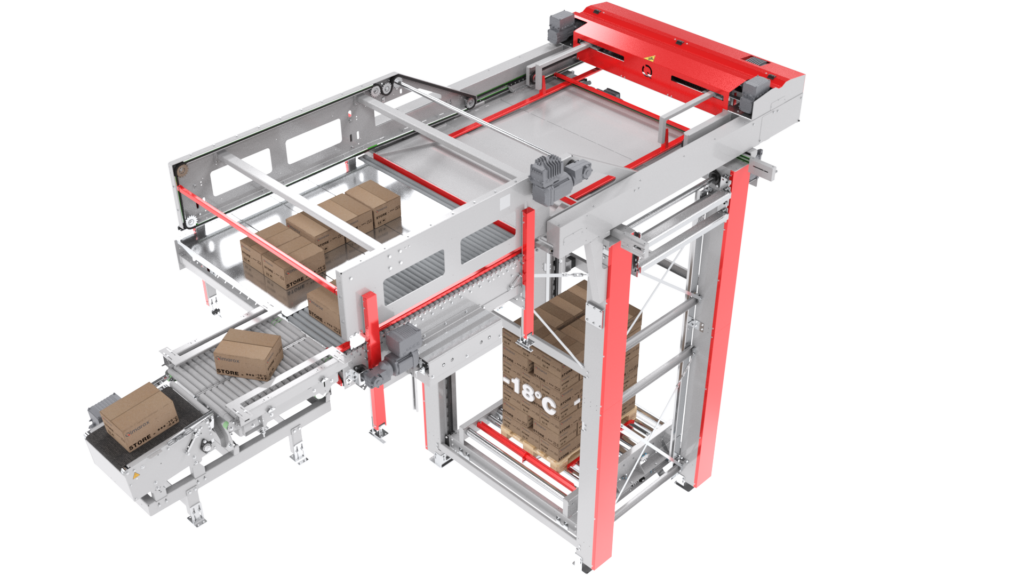

Palletizing Layer by layer

Another advantage is that the products are deposited on the pallet layer by layer with the Highrunner HR8. By depositing an entire layer at a time, the Highrunner HR8 needs to make fewer movements. This saves time, which increases the capacity.

Because the pallet moves up and down with a Prorunner mk10 vertical conveyor, the collated products no longer needs to be picked and moved up and down while being deposited. That saves even more time, especially with pallets that need to be stacked 1.80 metres or higher. This makes the Highrunner HR8 one of the fastest palletizers on the market. Not having the need to pick up products but only using - simple - pushing movements also increases reliability and less down time of the production line.

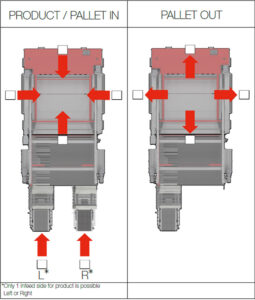

Infeed and outfeed of pallets

As soon as a pallet is full, the pallet lift moves all the way down so that it can be taken away via a pallet transport system. An empty pallet can be supplied from the opposite direction at the same time. This continues flow of pallets improves the time needed for pallet change over which is the most time consuming moment within any palletizing system and has a huge impact on overall throughput.

Why choose Qimarox?

Qimarox is a leading manufacturer of components for material handling systems. As a manufacturer of palletisers and product lifts, Qimarox distinguishes itself with a contemporary vision and approach. Innovation, quality and added value are of paramount importance.

Interested in a palletizing machine or another palletizing solution?

If you would like more information about our palletizing solutions, you can request a sales enquiry without any obligations. If you have any other questions please feel free to contact us!

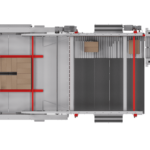

The Highrunner HR8 palletizer for IQF products is configured to deal with all challenges within the frozen food sector when it comes to palletizing. Several options are available for each module depending on the customer requirements and the products requiring palletization.

The specifications of the Highrunner HR8 palletizer for IQF products are:

| Specifications | Min. | Max. |

| infeed height at platform level (mm/inch) | 600 / 20 | 1.000 / 43 |

| Product dimensions (LxBxH mm/inch) | 200 x 200 x 100 / 8 x 8 x 4 | 400 x 300 x 400 / 16 x 11.5 x 16 |

| Thoughput (products/hour) | - | 900 - 1800* |

| Thoughput (layers product/hour) | - | 300* |

| Product weight (kg/lbs) | 1 / 1 | 25 / 55 |

| Layer weight (kg/lbs) | 1 / 1 | 180 / 400 |

| Footprint (m²/sq ft) | 7,4 / 80 | 7,4 / 80 |

* Capacity depends on product dimensions and stacking pattern

Benefits of the Highrunner HR8

- Unique method of pattern formation, where products are positioned on exact coordinates (patented)

- Vertical pallet conveyor Prorunner PR10 included, with automated drop-down safety

- Built-in buffer for depositing products in layers

- User-friendly touchscreen operation

- Pattern generator included

- Freely programmable stacking patterns

- Solid construction with perfect finishing for tough jobs

- Easy access for service and maintenance

- No more than 2.4 x 3.4 metres of space is required

- Standard machine with commercially available components

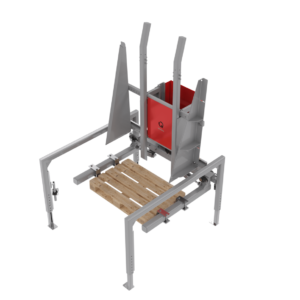

The HR8 palletizer for IQF products is available in different versions. The most important option relates to the infeed of products. You can choose from the following options:

- Side infeed - left

- Side infeed - right

- SSL layer handling (short side leading)

- LSL layer handling (long side leading)

In addition, the palletizer can be expanded with a number of additional modules:

- Twistrunner TR6: for turning products with full control on rotation

- Sheetrunner SR2: for placing a sheet of pre-cut cardboard or paper between two layers

- Sheetrunner SR3: for placing a sheet of paper from a reel between two layers