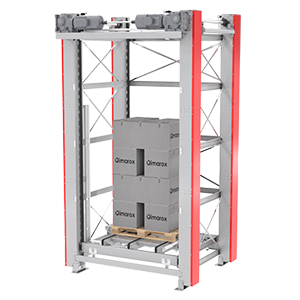

Qimarox offers various types of vertical conveyors for empty or loaded pallets which can be used in combination with our palletising modules or as stand-alone units in pallet conveyor systems.

A vertical pallet conveyor is a type of conveyor system that is used to transport pallets or other large items between different levels in a warehouse or manufacturing facility. Unlike horizontal conveyor systems, which move items along a single plane, vertical pallet conveyors lift items vertically, allowing them to be transported between different floors or levels of a facility.

Vertical pallet conveyors are often used in multi-level warehouses or distribution centers to move items between different floors or levels. They can also be used in manufacturing facilities to move items between different stages of the production process.

Companies may choose to use vertical pallet conveyors for several reasons:

- Space Saving: vertical pallet conveyor can help companies save space in their warehouse or facility by eliminating the need for large elevators or lift systems.

- Increased Productivity: vertical pallet conveyor can significantly increase the speed and efficiency of moving goods between different levels, which can help increase productivity and reduce labor costs.

- Flexibility: vertical pallet conveyors can be customized to meet the specific needs of a company’s warehouse or facility. They can be configured to move goods between different levels, or even to perform multiple operations such as assembly, packaging, and sorting.

- Safety: vertical pallet conveyors can reduce the risk of injuries caused by manual labor in moving heavy goods.

In summary, a vertical pallet conveyor can be a valuable investment for companies that need to move large items between different levels in their warehouse or facility, as they can help increase productivity and efficiency while saving space and reducing labor costs.