Palletizing solutions by Qimarox

Palletization or palletizing is a logistic process which consist of placing items/goods stacked together on a pallet. The goal of this process is to make it easier for a manufacturer to transport their loads.

Pallet

A pallet is a square platform usually made out of wood, plastic or metal, provides the fundament for the products to be stacked on top of. Pallets have holes for a forklift or pallet jack to pick up and move the load all together for quick material handling. Palletizing also helps to protect the items/goods when it is being transported by creating stacking patterns which add stability to the pallet as a whole. When palletizing your items/good, the type of pallet you choose is fundamental. Therefore, you not only need to consider the material it’s made, but also their measurements: GMA pallets, half pallets, and Euro pallets are the most common used.

When considering which pallet you will need to use you should consider these factors:

- Which storage systems are you using.

- Which storage system do your clients use.

- The type of the products which his being palletized.

- Which handling equipment do you have (manual or automatic).

Palletization Solutions – Palletizers

A palletizer or palletiser is a machine which provides automatic means for stacking cases of goods or products onto a pallet. In the past this was done manually, this was time consuming, expensive and hard labor for the workers. The first mechanized Palletizer was designed, built, and installed in 1948 by a company formerly known as Lamson Corp. Since then the original concept has been improved many times and nowadays you have a variety of different palletizing solutions. A few different palletizing solutions are:

conventional layer palletizers: high-level (high input) and low-level (low input) * High-level layer palletizers are constructed in such a way that the wooden pallet receives the layers of parcels on the floor, then goes down as the layers are added. * Low-level layer palletizers are built so that the wooden pallet remains on the lower floor, and the layers of packages are mounted higher and higher.

The other option is are the Palletizing robots. Palletizing robots are enclosed in a security zone to protect operators. A palletizing robot is equipped with one or more gripping heads to perform different tasks at a time.

The reason for these development is there is a variety of different materials to palletize. You can think of things like:

Bags, boxes, crates, tray’s and more. Each of these items have their own ways of handling. The one is more delicate then the other. Also the products inside of the items may vary a lot which also means they could need different handling. For example glass can break easily, while clothes cannot.

The benefits of palletization

There are a lot of reasons why manufacturers choose to palletize their products. The main reason why palletization in logistics is so popular is because of the many advantages that it brings. That is also the reason why the pallet is now the standard unit load for warehousing and material handling. Benefits of palletization are:

- Palletized products can be moved more quickly.

- Reduce the risk of product damage

- Faster turnaround of delivery vehicles.

- Less labor required.

- Perishable products are moved faster, reducing the risk of perishing.

- Palletizing is cost effective compared to traditional material handling

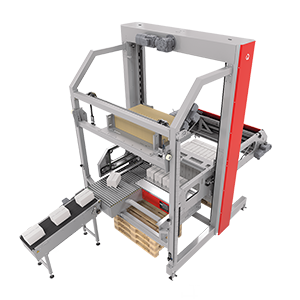

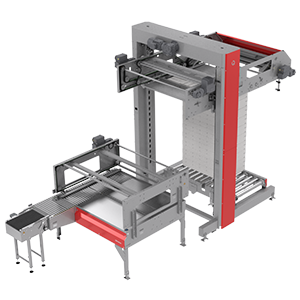

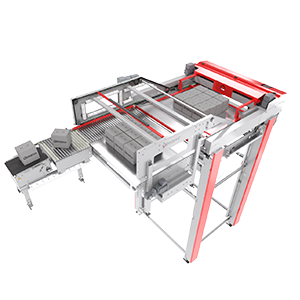

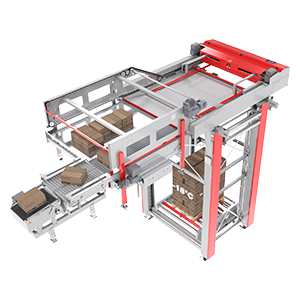

Palletizers from Qimarox

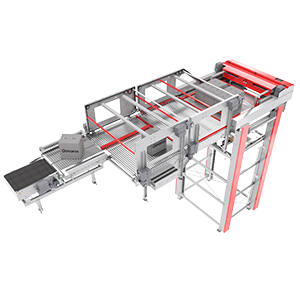

Qimarox supplies various palletising modules, from pattern-formation tables to high-capacity systems. All our palletizers form products with an extremely high degree of accuracy. We offer: