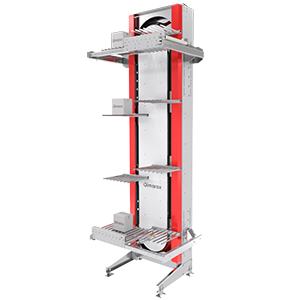

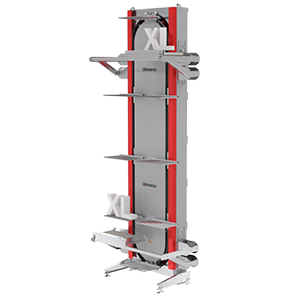

Qimarox is very well known from its Prorunner mk5 vertical conveyor, but we have more vertical conveying solutions to offer, all capable of transporting your products to any level of your facility.

A vertical product conveyor is a type of conveyor system that is used to move products or materials upward or downward in a vertical manner. It is typically composed of a series of interconnected belts, rollers, or other similar components that are arranged in a vertical configuration.

Companies may choose to purchase and use a vertical product conveyor for a variety of reasons. One reason is to save floor space. Because the conveyor moves products vertically, it does not require the same amount of horizontal space as a traditional horizontal conveyor system. This can be particularly useful in facilities that have limited floor space.

Additionally, vertical product conveyors can be useful for moving products to different levels in a facility. For example, they can be used to move products from a ground level production area to an upper-level storage area, or vice versa. They can also be used to move products between different levels of a multi-story building.

Another potential benefit of using a vertical product conveyor is that it can help to improve the efficiency and productivity of a facility. Because the conveyor can move products quickly and reliably, it can help to reduce bottlenecks and delays in the production or distribution process.

Finally, they can also be useful in safety, with vertical conveyors operator can avoid the danger of climbing ladders or working at height with elevated loads.