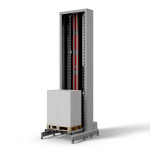

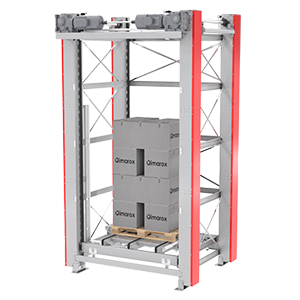

The Prorunner mk9 is a vertical pallet conveyor that automates the transport of pallets by lifting and/or lowering the pallets to the desired level of your facility. No manual labor is required anymore when you choose for the Prorunner mk9

Pallet lift Prorunner mk9

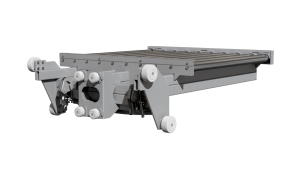

The Prorunner mk9 is a rugged pallet lift that automates the transport of pallets by lifting and lower ing the pallets to the desired level of your facility. The Prorunner mk9 is the perfect solution for capacities of up to 100 pallets per hour. Because of its extremely small footprint, this lift fits into virtually any layout. This compact vertical pallet conveyor is very easy to integrate into your transport system and can be equipped with a roller conveyor or chain conveyor. Thanks to the design and highly reliable components, the machine hardly requires any maintenance. In short: an easy-to-integrate pallet lift that also is affordable.

Robust Pallet lift

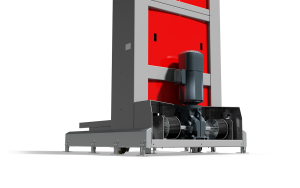

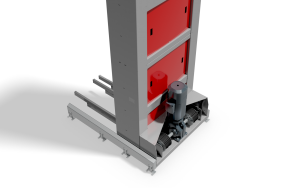

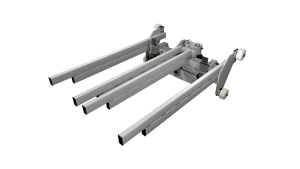

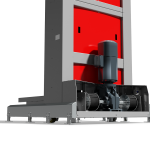

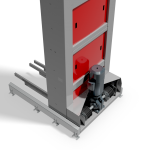

The robust and compact pallet lift effortlessly moves pallets weighing up to 1,250 kilograms (2,760 lbs) over a vertical distance of ten meters. The modular construction makes the lift durable and maintenance-friendly and is easy to integrate into any environment. Because the complete construction and drive is integrated on one side, pallets can be fed in or out from three sides. It is also possible to operate several infeed or outfeed conveyors with one machine, so that the lift can be used for vertical sorting, for example. The drive consists of a SEW electric motor as standard, which can be mounted at floor level or at the level of the mezzanine, depending on the customers preference.

Why choose Qimarox?

Qimarox is a leading manufacturer of components for material handling systems. As a manufacturer of palletisers and product lifts, Qimarox distinguishes itself with a contemporary vision and approach. Innovation, quality and added value are of paramount importance. For more information on our Prorunner mk9 watch this YouTube video of how it was integrated by a system integator.

Interested in the Vertical pallet conveyor - Prorunner mk9 or another vertical transport solution?

If you would like more information about our vertical conveyor solutions, you can request a sales enquiry without any obligations. If you have any other questions please feel free to contact us!

The specifications of the vertical pallet conveyor Prorunner mk9 are:

• Lowest infeed/outfeed position of the mk9: 500 mm / 20 inch

• Highest infeed/outfeed position of the mk9: 10,900 mm / 420 inch

• Max. column height: 10,950 mm / 47 feet

• Max. pallet weight: 1250 kg / 2,760 lbs

• Max. pallet size: 1,300 x 1,250 mm / 51 x 49 inch

• Max. throughput: 100 pallets p/hour

Advantages of the vertical pallet conveyor Prorunner mk9 are:

- Minimal footprint

- Right-angled setup also possible

- Suitable for vertical sorting (multiple floors)

- Pallets, racks, etc. up to 1,250 kg

- Sturdy, low maintenance machine

- No chains need lubricating or tightening

- It makes minimal operating sound

- Solid steel construction

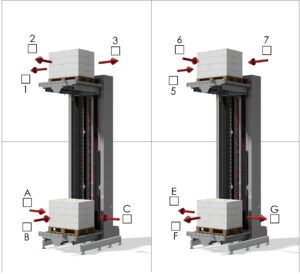

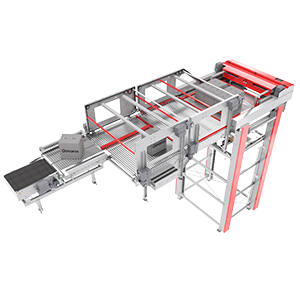

Prorunner mk9; In- and outfeed in three directions

The Prorunner mk9 does its job in almost any conceivable situation. Not only is the productlift suitable for left or right side product infeed or outfeed, when using a suitable product carrier also via the front.

For selecting the configuration that suits your situation best, you simply follow the road map in which the various possibilities are clearly compared next to one another. By means of the adjacent drawing you select the required in- and outfeed situation. You can find the accompanying 3D drawing by means of the table below.

Example:

You want to lift (elevate) products, infeed at the left side and outfeed via the front side. In that case you select combination A2. If you want to lower the product (descend) and infeed and outfeed at the right side, then selection combination 6F.