The canned fruit and vegetable factory produces almost one million cans, jars and bags with long-life products every day. Due to an increase in efficiency, the need arose to increase the capacity of the palletizing machines. A special innovation from Qimarox (manufacturer of the palletizers) has increased the capacity by 25 per cent. Plant manager: ‘At the same time, the quality of stacking on the pallets has also improved.’

Every year, the canning factory processes many millions of kilograms into products that are packaged in glass, tin cans or pouches. These products are found in the stores of almost every major supermarket chain in the world, often under private labels but sometimes also under their own brand. “We supply retailers in more than sixty countries, such as Wal-Mart, Aldi, Lidl, Carrefour, Tesco and Jumbo,’ says the plant manager.

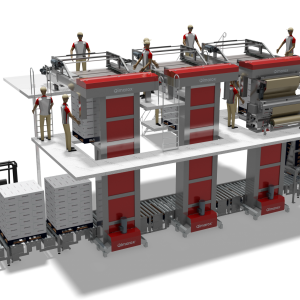

Once the products have been processed and packed in glass or tin and bundled on trays, they are placed on pallets. Since 2009, the company has been using palletizers from Qimarox, a global supplier of material handling components. To the full satisfaction of the engineering manager at the canning factory: ‘The four machines we had before were very inefficient and required a lot of manual work. Now all we need is Qimarox’s three palletizers, while saving four to five people.

Bottleneck

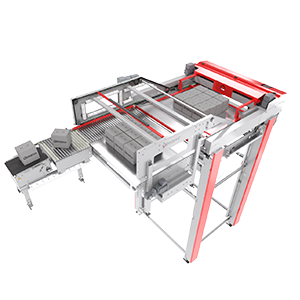

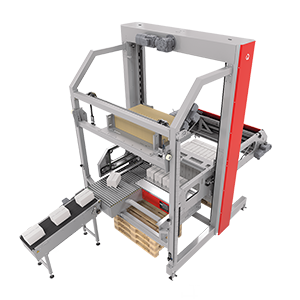

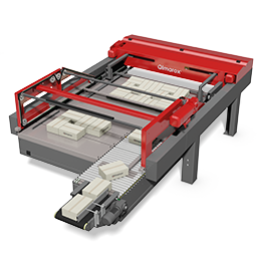

Qimarox increases palletizing capacity through smart innovations. Qimarox’s three palletizers are so-called ‘Highrunners’. This means that the trays with products are supplied at height and are slid onto a pallet layer by layer. After each layer, the pallet descends exactly enough to be able to palletize the next layer of trays in an identical manner. When the pallet is full, it is automatically wrapped in foil, labelled and removed via the roller conveyor located underneath the three palletizers. The roller conveyor transports the pallets, after wrapping and labelling, to an automatic storage system, where they remain until they are transported. Once the truck has arrived, the pallets are loaded fully automatically. Since the installation of the Qimarox machines, no human is needed for any of this entire process.

The capacity of the palletizers is crucial in this whole process. This must be higher than the capacity of the production lines, so that production does not stagnate because the trays are not stacked on pallets quickly enough. For years, a lower capacity was not a problem. Until recently. ‘In recent years we have succeeded in continuously increasing the capacity of our production lines through all kinds of improvements,’ explains the engineering manager. ‘As a result, the palletizers were in danger of becoming a bottleneck. We were therefore forced to further increase capacity.’

Measuring and correcting

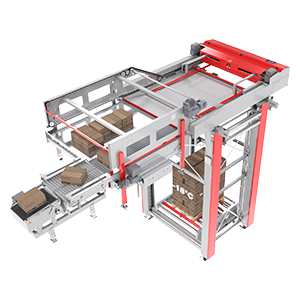

Qimarox increases palletizing capacity through smart innovations. The innovation concerns the way in which the trays are rotated in order to be able to stack them in the right pattern. Until recently, Qimarox used two parallel roller conveyors for this purpose. The trays that are supplied over these roller conveyors are automatically rotated a quarter turn by varying the speed of both roller conveyors a fraction of a second. ‘This is a technique that works well as long as the supply velocity remains limited. As speed increases, so does inaccuracy. This leads to malfunctions and therefore to stagnation,’ explains the engineering manager.

The innovation consists of a smart sensor that continuously measures the position and orientation of the trays. If this sensor detects that a tray has been turned too much or too little, the operating software intervenes immediately, and a correction is made automatically. ‘Last year, we tested this innovation on a single palletizer. The result was an increase in capacity that was more than enough to also convert the other two machines,’ says the engineering manager. The plant manager adds: ‘An additional advantage is that pallet stacking quality has also been improved. Occasionally a tray would slip past that wasn’t turned enough. This leads to unstable stacks with a protruding tray. This can lead to problems in our warehouse, where we set strict requirements for the contours of pallets due to the high degree of automation. Complaints about this have been considerably reduced.’

Innovation and flexibility

The canning factory praises the innovation of Qimarox. This was one of the reasons for choosing palletizers from this Harderwijk machine builder in 2009. ‘It is a stable company with a great deal of knowledge and know-how, that takes a proactive approach towards finding solutions to customer questions. Qimarox’s decision to concentrate on the development and production of machines has resulted in a fast and efficient palletizer with a good price/quality ratio. Qimarox has become the market leader for palletizers, but at an attractive price,’ says the engineering manager, who has many years of experience with Qimarox machines.

The company’s innovativeness is also reflected, for example, in the flexible way in which stacking patterns can be introduced. The canning factory can now do this itself without having to call in a software programmer. ‘A big advantage is that we can also quickly change stacking patterns during production. As a result of market developments, we have been producing in ever smaller batches over the years, which means that stacking patterns are changing more and more frequently. In the past, we had to change the machines to deal with these changes, but this is no longer necessary. When we click on a different stack pattern, the machines set themselves. If we use a different pallet size, the right pallet will automatically be supplied from the pallet warehouse.’

Reliability

The plant manager praises the reliability of the palletizers. ‘Faults are few if any. The palletizers have never been in our top ten of machines that are susceptible to faults,’ explains the plant manager. The engineering manager agrees with him. ‘In addition, the machines are made up of standard parts that are widely available. If ever a fault does occur, we can quickly and easily replace the parts ourselves.’

After the upgrade of the palletizers, the canning factory will be able to move forward again. The production lines can now increase five percent in speed again, while the palletizers can now process up to more than 600 cans per minute. The plant manager: ‘That’s more than enough to be able to keep up with our preliminary process. We expected that this will keep everything running smoothly for the foreseeable future.’