The Qimarox Palletizers are:

Qimarox offers a select range of palletizers within our portfolio, featuring both low-infeed and high-infeed options. We specialize in plate palletizers and do not manufacture robotic (arm) palletizers

- Lowrunner LR3

- Highrunner HR8 – IQF Products (Vegetables, Fruits & Fries)

- Highrunner HR9 – For logistic operations

Each Qimarox palletizer features a unique, patented design that sets it apart in functionality and operations. Our available palletizer models are:

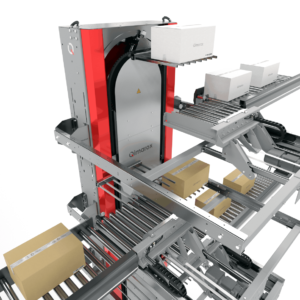

The integration of a palletizer, or a palletizing machine into logistics, production, and various industrial operations is a strategic investment that offers substantial benefits across multiple dimensions of the business. Automating the palletizing proces offers several advantages:

Labor Efficiency and Safety: Automating the palletizing process reduces the need for manual labor in potentially hazardous tasks, such as heavy lifting.

Cost Savings: While the initial investment in a palletizing machine may be significant, the long-term savings on labor, improved efficiency, reduced product damage, and optimized space utilization contribute to a strong return on investment.

Optimized Space Utilization: Palletizers precisely stack items, maximizing space utilization in storage facilities and on transport vehicles.

Increased Productivity: By automating the end-of-line process, palletizing machines significantly increase production throughput.

Consistency and Quality Assurance: These machines ensure that products are stacked securely and consistently, minimizing damage during handling and transport.

Palletizers

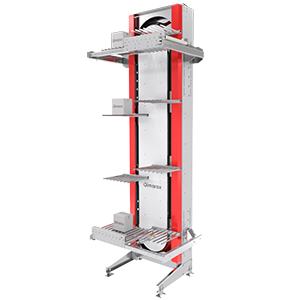

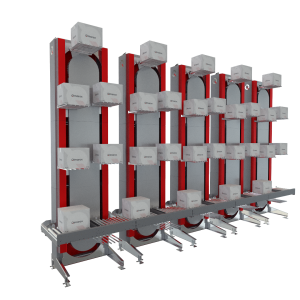

Lowrunner LR3 – palletizer

The modular palletizer Lowrunner LR3 from Qimarox is a palletizer with a capacity of up to 1,500 packages per hour

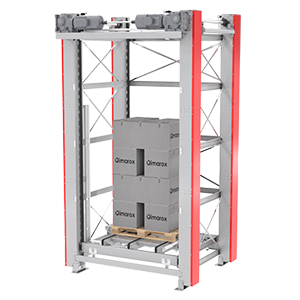

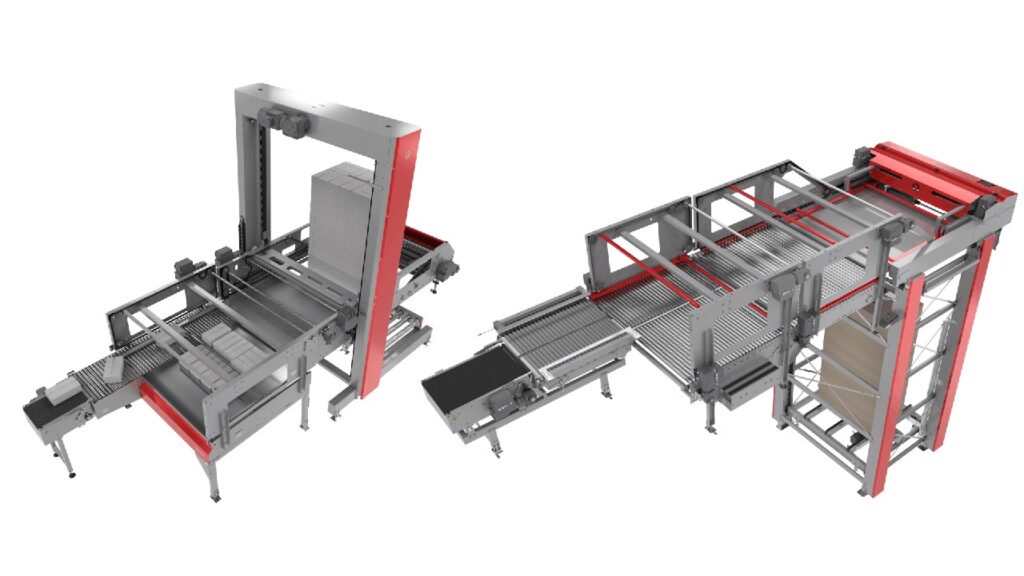

Highrunner HR8 – palletizer

The Highrunner HR8 is designed for palletizing cartons containing frozen food – mainly vegetables, fries & fruits. It has a handling capacity of 900 – 1800 products per hour.

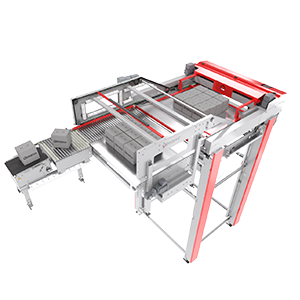

Highrunner HR9 – palletizer

The Highrunner HR9 is designed for the logistics industry and it has handling capacity of 500 – 1,500 products per hour.

This is what one of our end-users had to say:

“And importantly, we can now act and adapt more quickly when production switches to a different product, effectively increasing our capacity even more, even if the stacking pattern changes in between. Additionally, we can now handle interleaf sheets,” Berndsen – Remia